Artificial Intelligence has become a powerful partner to the manufacturing sector. The day-to-day operations on the factory floor are enhanced by intelligent systems that bring a new level of precision and foresight to the way manufacturing businesses operate. For business leaders, keeping pace with these developments is key to building resilient and competitive companies.

This blog post offers a look at the practical role of AI in modern manufacturing. It details specific ways that AI is applied on the production line and breaks down its direct benefits for efficiency and quality.

AI plays a central role in the next generation of factory automation. Our goal is to give you a clear, straightforward understanding of how these tools solve real and pressing challenges on the factory floor.

How AI Is Used in Manufacturing

AI in manufacturing involves using computer systems to perform tasks that typically require human intelligence. This includes learning from data, recognizing patterns, predicting outcomes, and automating decisions.

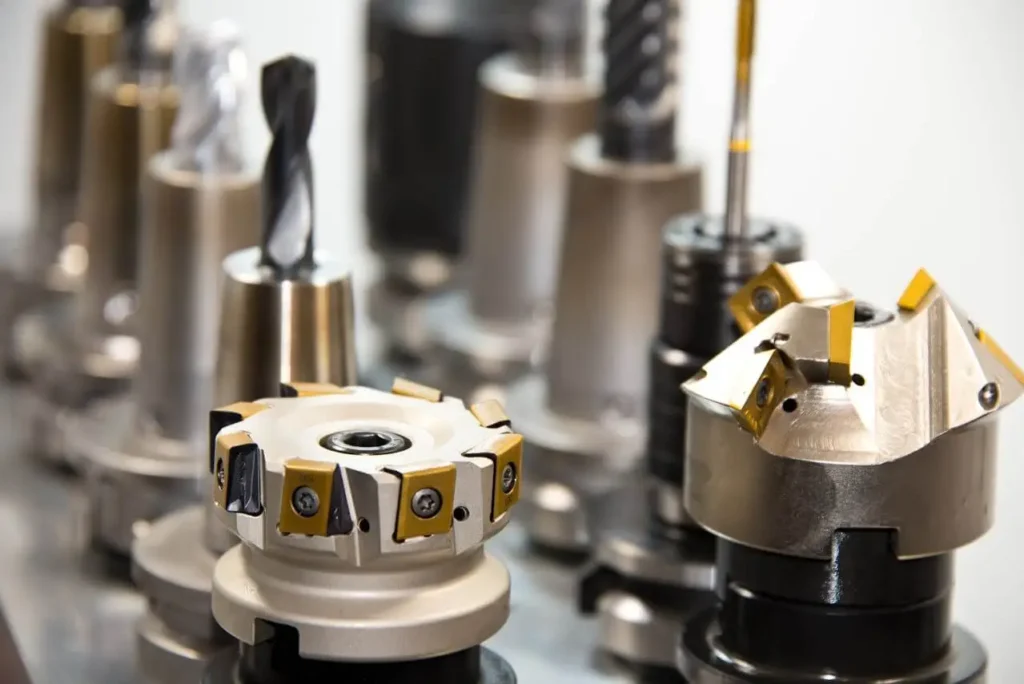

In factories, AI is applied to create smarter and more efficient operations. Here are some of the key applications:

- Predictive maintenance: Instead of following a fixed maintenance schedule or waiting for a machine to break down, AI analyzes data from sensors on equipment to predict failures before they happen. Maintenance can then be performed only when necessary, preventing costly unplanned downtime.

- Quality control: AI-powered vision systems inspect products faster and more accurately than the human eye. They identify microscopic defects that would otherwise go unnoticed, improving consistency and quality.

- Production planning and supply chain management: AI forecasts demand, manages inventory, and identifies potential disruptions. This ensures that resources are allocated in the most effective way possible.

The Benefits of AI in Manufacturing

The practical applications of AI translate directly into business advantages. Companies that integrate AI into their processes report significant improvements across several key performance areas.

Increased Efficiency

AI improves efficiency by streamlining multiple parts of the production process. Algorithms optimize production schedules by considering variables like machine availability and material supply. On the factory floor, AI coordinates the work of autonomous mobile robots (AMRs), that transport materials without human input, reducing waiting times and speeding up workflow. This shortens production cycles and increases the output of existing assets, allowing factories to produce more with the same resources.

Cost Reduction

Predictive maintenance reduces costs associated with emergency repairs and prolonged production halts. By reducing defects, AI quality control systems lower the costs of rework and warranty claims. AI also contributes to energy saving as smart systems monitor and adjust energy consumption across the factory, powering down non-essential equipment and adjusting heating and cooling. Together, these lead to a substantial decrease in operational expenses.

Enhanced Quality Control

Advanced computer vision systems trained on thousands of product images can detect anomalies and subtle variations in assembly that are invisible to human inspectors. This improves the overall quality of the final product and builds a database of defect information. Over time, AI can trace these defects back to their root cause in the production process, such as a specific machine issue. This allows for continuous improvement and fewer errors overall.

The Role of AI in Advancing Factory Automation

Factory automation is shifting from rigid, pre-programmed systems to flexible, self-improving networks. In this environment, AI enables different systems to communicate and collaborate, turning the entire production floor into a connected adaptive ecosystem.

AI is also paving the way for emerging technologies and sustainable practices. Its expanding role includes:

- Strengthening traceability with blockchain: AI works in tandem with blockchain to log every step of a product’s journey. It collects data on each component and production step, which is then securely logged on a blockchain. This improves traceability, which is important for verifying authenticity and ensuring regulatory compliance in industries such as aerospace and pharmaceuticals.

- Promoting sustainable manufacturing: AI helps optimize energy usage and reduce material waste through precise manufacturing. It even helps to design more sustainable products. By analyzing data across the supply chain, AI also helps companies select more sustainable materials and logistics options, reducing their overall carbon footprint.

- Enabling generative design: Engineers use AI-powered generative design tools in product development. They simply input design goals and constraints, and AI explores thousands of design possibilities. The result is more efficient and robust structures that a human engineer might not have thought of.

- Creating a safer work environment: AI-powered cameras and sensors monitor the factory floor to identify potential safety hazards, like a worker entering a restricted zone or a spill in a walkway. The system can then immediately alert personnel or trigger an automatic shutdown to prevent accidents before they happen.

Ready to Transform Your Manufacturing Process with AI? Contact Us Today

The journey from a traditional setup to an AI-powered smart factory may seem complicated, but you don’t have to do it alone. At AI First Mindset, our team of experts will guide you every step of the way. We specialize in developing AI strategies that address your specific challenges. Whether you need to improve production line efficiency or implement smarter quality control systems, get in touch today.

Conclusion

AI in manufacturing provides solutions to long-standing industry challenges and offers a clear path to increased efficiency and cost reduction. The answer to “How is AI used in manufacturing?” is multifaceted and transformative. By understanding and adopting these technologies, manufacturers can build stronger, more competitive operations, ready for the demands of the future.

Q&A

How Does AI Reduce Costs in Manufacturing?

AI reduces costs by eliminating major sources of financial waste. It enables predictive maintenance, preventing expensive machine downtime and repairs. AI-powered quality control systems drastically reduce material scrap and product rework by catching defects early.

How Does AI Improve Decision-Making in Manufacturing?

AI improves decision-making by turning factory data into actionable insights. Instead of relying on intuition or historical averages, managers can use AI to forecast demand accurately, simulate production outcomes, and identify the root causes of problems.

Is AI in Manufacturing Expensive to Implement?

Implementation costs vary widely. While there are upfront costs for sensors, software, and expertise, AI is no longer limited to large corporations. The modern AI-as-a-Service models and scalable cloud platforms have made it more accessible.

Recent Posts

-

Published on: October 14, 2025

-

Published on: October 7, 2025

-

Published on: September 23, 2025